"How will product designers work in the future? How can products be created with generative design programs?"

My bachelor thesis deals with these questions and analyses different fields of applications for generative design based on three experimental examples.

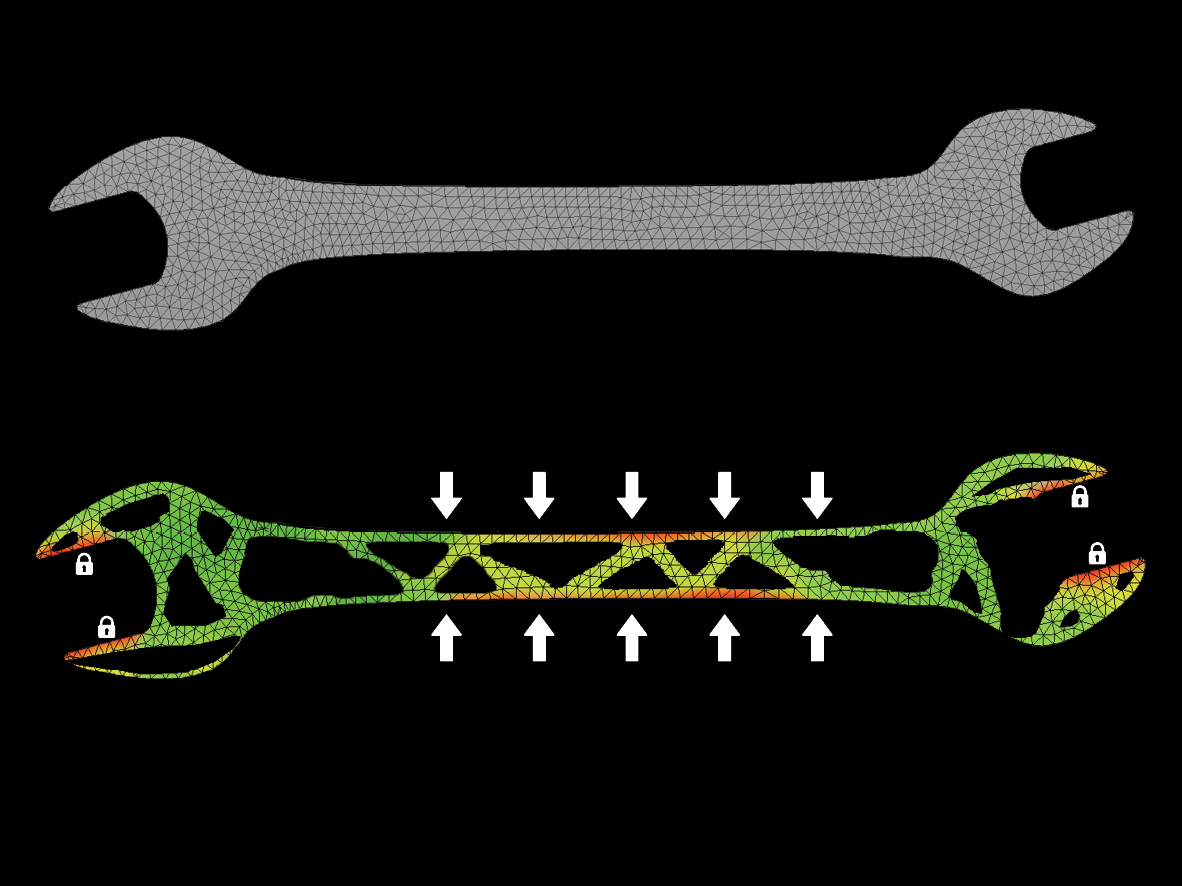

topology optimization

LIGHT TOOL

The study has three different research fields. One of them is topology

optimisation, in which the product´s shape is optimised. Therefore, making an analysis is necessary, where the material of the volume and its parameters like stress on the body are defined.

As a result the software shows how you could improve the form and reduce material. To showcase how the process works and how product designers could use the tool, I showed it on

an open-ended

spanner.

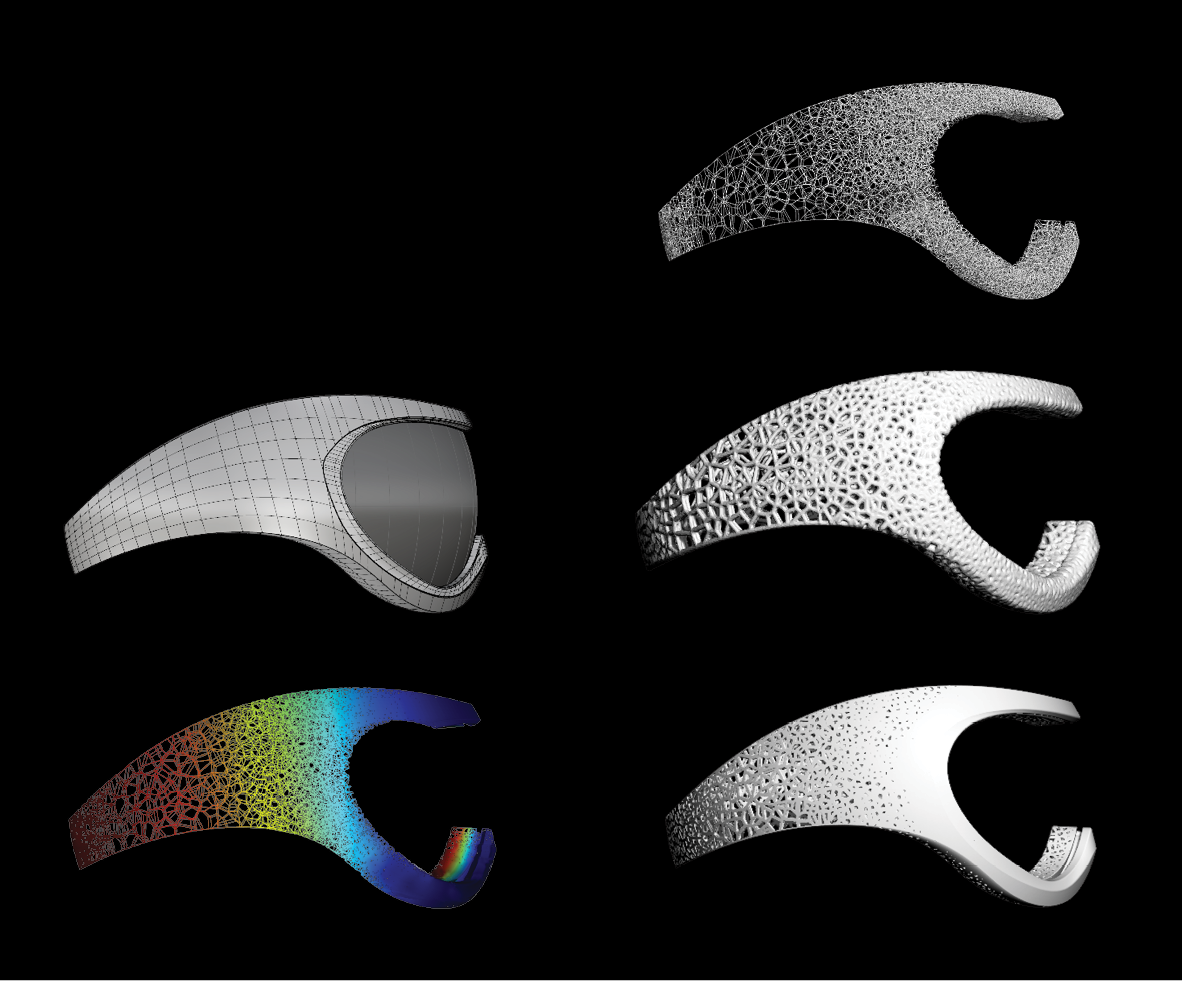

trabecular structures

LATTICE GOGGLES

Trabecular structures are providing the possibility of enabling different properties like high stiffness or flexibility by using one material. The big difference that is used is the structure. Therefore, thicker structures are increasing stiffness and thiner ones make the product more flexible. Advancing this technique of trabecular structures made it possible to create a ski goggle out of one material with varying properties and thereby having a futuristic design.

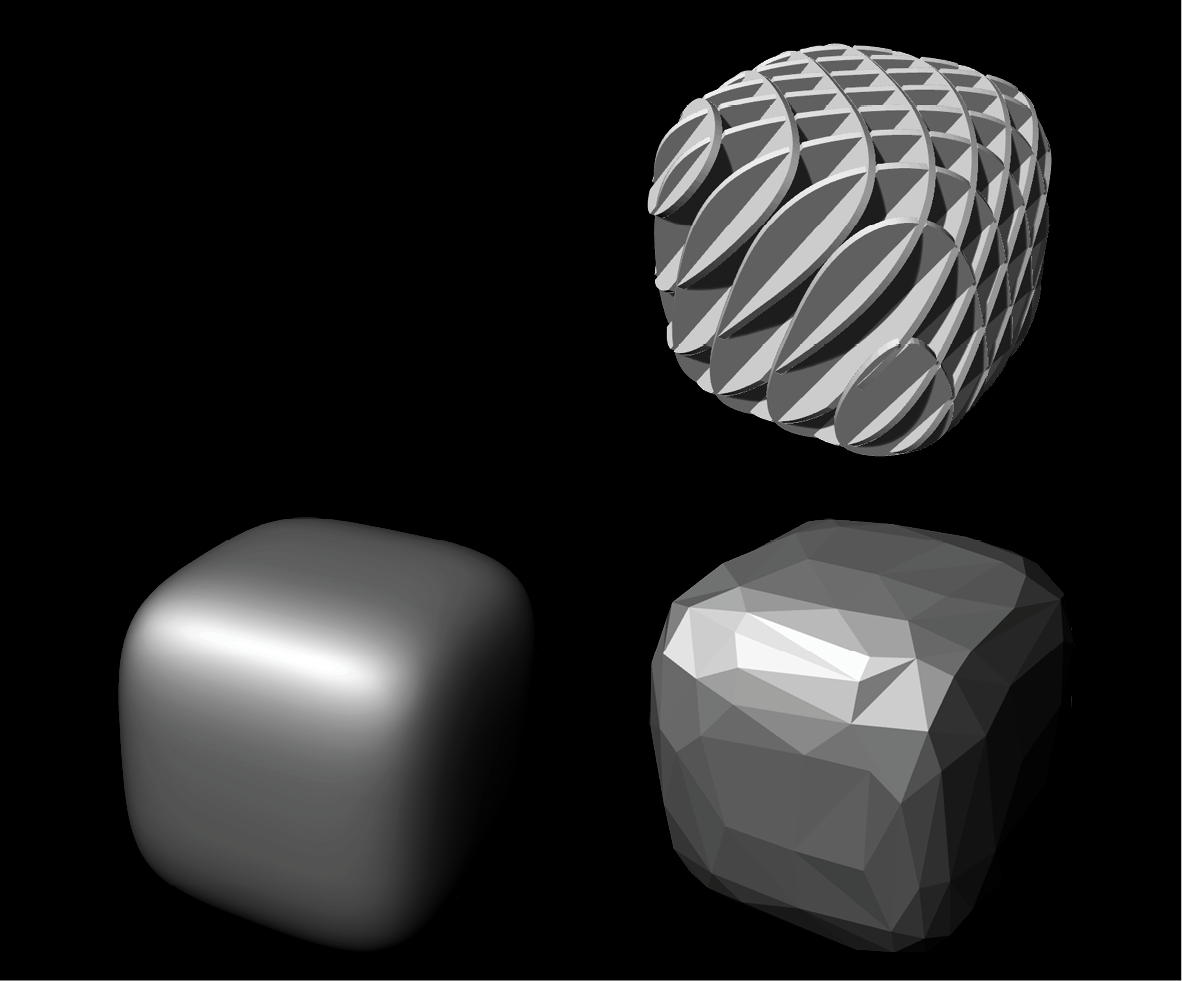

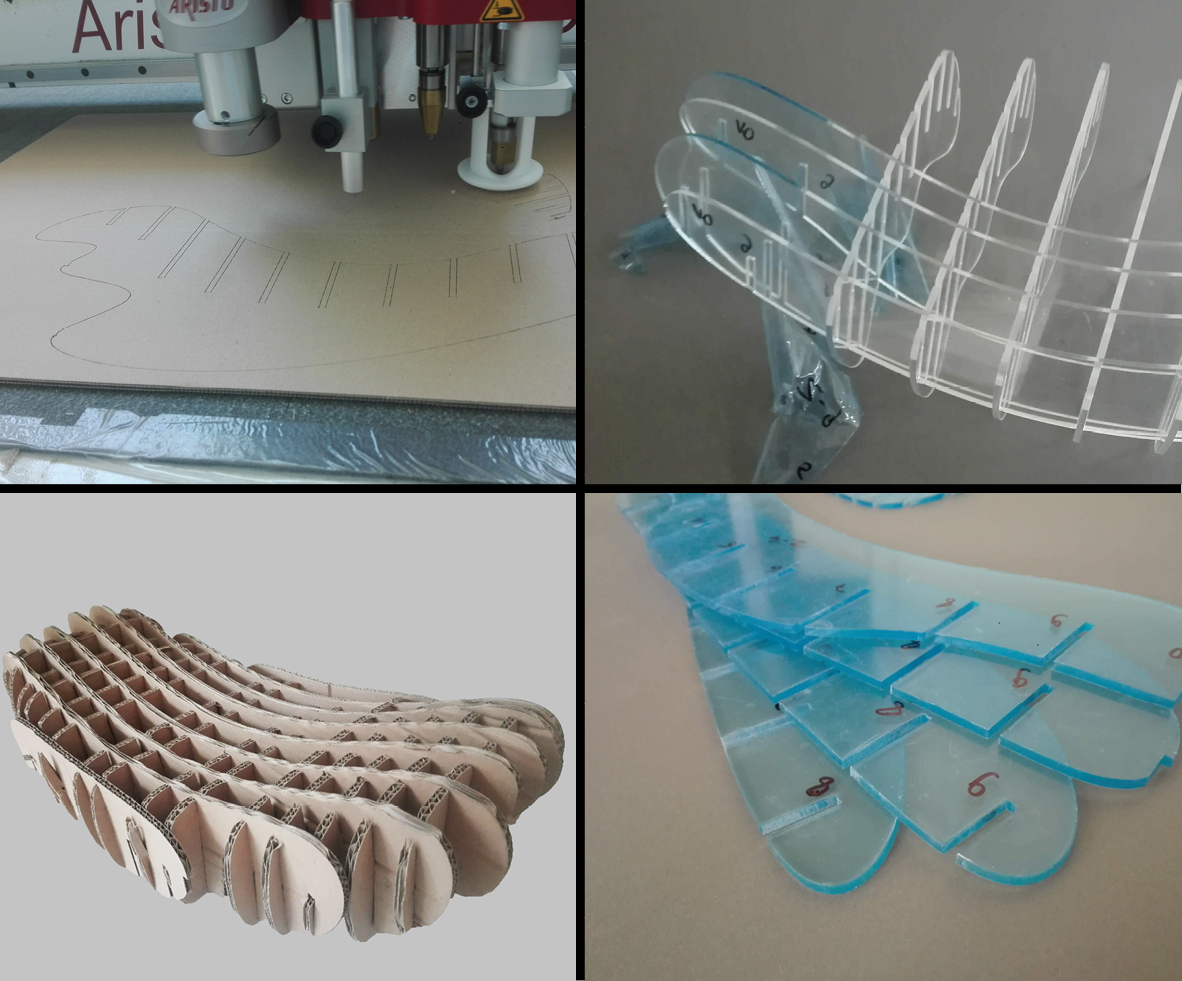

parametric structures

INTERLACED SWING

Parametric structures are very well known in the field of architecture. For instance, Zaha Hadid and Frei Otto used this technique for their outstanding architectural designed buildings.

Combining the technique with manufacturing methods like laser cutting makes it possible to create organic structures based on two-dimensional materials. To represent one of the endless possibilities, I designed a swing made from interlaced structures. The structure is extraordinary as it requires no binding material such as glue or screws.

Bachelor project

Supervisors: Prof. Matthias Held, Prof. Franz Biggel

Hochschule für Gestaltung Schwäbisch Gmünd